Risk Assessment Guidelines

A risk assessment is the process of identifying hazards that currently exist or may appear in the workplace. It defines which hazards are likely to cause harm to employees and visitors and analyses the measures in place to control the risks.

Although sometimes used interchangeably, the terms hazard and risk have slightly different meanings. A hazard is something that can cause harm, e.g. electricity, chemicals or working at height. A risk is the likelihood of a person being harmed by the hazard – is there a low, medium or high chance of injury or adverse health effects?

Legal requirements for risk assessment

Employers are required by law to protect their employees, and others, from harm. Under the Management of Health and Safety at Work Regulations 1999, general risk assessments must be completed by all employers; additionally, those with five or more employees must record significant findings. Risk assessments apply to lone workers as well as those working in large teams and should be updated as required.

Read health and safety legislation guide for more detailed information about employer’s legal requirements.

Five step guide for risk assessment

Conducting a risk assessment is a step-by-step process that should be undertaken by management with the involvement of everyone at the workplace: the employers, management and workers and/or their representatives. Each of these groups will provide valuable input to the different stages of the process.

A risk assessment involves the following steps:

- Identify hazards

- Identify who is at risk

- Assess the risks

- Consider if risks can be eliminated

- Decide on further measures

Identify hazards

One of the most important aspects of a risk assessment is accurately identifying the potential hazards in the workplace. A good place to start is simply walking around the workplace thinking about things with the potential to cause harm. Observe the activities, processes and substances used that could inflict injuries or negatively impact someone’s health:

- What tasks are people doing?

- How is plant and equipment being used?

- What chemicals and substances are being used?

- What unsafe work practices exist?

- What is the general state of the premises?

Speaking to workers is a useful exercise to identify hazards because they might be aware of unsafe practices that haven’t been reported. Think about hazards to health such as manual handling, working at height and causes of work-related stress.

To identify less obvious hazards, look over the accident book and other records that track near misses and incidents of ill health. Also, take non-routine operations such as maintenance and cleaning into consideration.

Identify who is at risk

For each hazard, the risk assessment needs to be clear about who might be harmed thinking not just about employees, but also contractors, visitors and members of the public where applicable.

Take into account people interacting with the hazard either directly or indirectly. For example, a worker painting a surface is directly exposed to solvents in close proximity, while other workers in the vicinity are inadvertently and indirectly exposed.

Particular attention should be paid to groups of workers who might be at increased risk, such as:

- staff with disabilities

- young and old workers

- pregnant women and new mothers

- untrained or inexperienced staff (e.g. new recruits, seasonal and temporary workers)

- lone workers

- migrant workers

Assess the risks

Having identified the hazards and the people at risk, the next step is to decide how likely it is that harm will occur. In other words, determine the level of risk and evaluate the control measures currently in place.

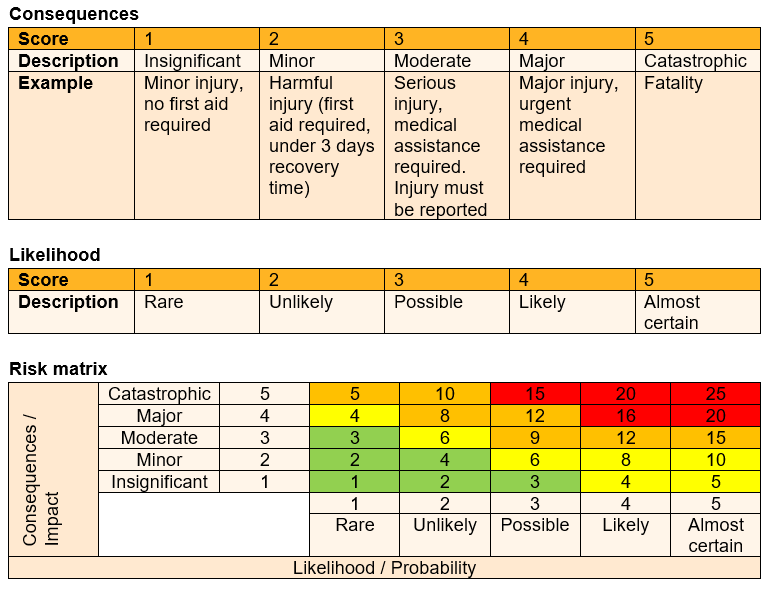

The easiest way to do this is by having a risk matrix: a diagram used to define the level of risk by considering the category of probability or likelihood of an incident occurring against the category of consequence severity. Each category will be given a score, typically between 1 and 5. By multiplying the scores for likelihood and consequences together, a total risk score will be produced for each activity.

In the above example, there are four risk levels: low (green), medium-low (yellow), medium-high (orange) and high (red).

If the risk level is either low or medium-low, additional safety precautions that could reduce the risk further could be considered if they can be easily implemented and at minimal cost.

If the risk level is medium-high, additional safety precautions that could reduce the risk should be considered, but the effort and cost of their implementation may be taken into account.

If the risk level is high, additional safety precautions that will reduce the risk must be implemented.

Consider if risks can be eliminated

Look at what is currently being done and the risk controls already in place. The first option for reducing risk should always be to try and remove the hazard. For example, windows on tall buildings might be designed so that they can be cleaned from the inside, rather than relying on potentially difficult external access.

If it’s not possible for the hazard to be eliminated, think about how the risks can be controlled so that harm is unlikely.

Decide on further measures

Employers are not expected to eliminate all risks but must do everything that is ‘reasonably practicable’ to protect people from harm. This involves balancing the level of risk against the measures needed to control the hazard in terms of money, time or trouble. If further controls are necessary, consider:

- redesigning the job

- preventing access to the hazard

- replacing the materials, machinery or process

- organising work to reduce exposure to the materials, machinery or process

- providing personal protective equipment (PPE) and make sure workers wear it

- running additional and refresher training sessions

Improving health and safety doesn’t need to cost a fortune. For example, almost a quarter of all deaths involving workplace transport involve drivers reversing; by using a one-way system and planning routes, the need for drivers to reverse is minimised, simultaneously maximising visibility.

Record risk assessment findings

Make a record of significant findings (as previously mentioned, this is a legal requirement if you have five or more employees) – the hazards, how people might be harmed by them and the control measures in place to reduce the risks.

The HSE provide a risk assessment template which you can download as well as example risk assessments to demonstrate how certain businesses would manage risks. They can be used as a guide to think about hazards and the steps needed to control the risks.

A risk assessment is required to be ‘suitable and sufficient’, showing that:

- a proper check was made

- all obvious significant hazards have been dealt with, taking into account the number of people who could be involved

- the precautions are reasonable, and the remaining risk is low

- employees or their representatives were involved in the process

If the risk assessment identifies a number of hazards, they should be ordered in terms of importance with the most serious risks being addressed first. Design an action plan based on this information and communicate it to all employees.

Review risk assessment

As a minimum, risk assessments should be reviewed annually to evaluate the control measures in place to ensure they are working. During this time, new hazards such as new machinery, substances or procedures may have been introduced.

A review may need to take place sooner in the event of an incident, near miss or a problem spotted by an employee. Similarly, the original assessment may no longer be applicable if the data or information on which it is based are no longer valid.

It’s important to keep risk assessments up to date, particularly where the nature of work changes fairly frequently or the workplace changes and develops (e.g. construction site). Employers are advised to set up regular reminders to review risk assessments.

HSE Fines

Where a workplace incident occurs as the result of a breach of health and safety regulations, employers can face criminal proceedings and be fined up to £10 million by the HSE. With conviction rates as high as 93% employers should do all they can to comply with legislation and protect their staff. Calculate how much you could save on HSE fines by implementing an employee safety service: